Choosing the right plastic roll for your packaging needs is crucial. The market offers numerous options, making it overwhelming. Each type serves specific purposes, and understanding them is essential.

Plastic rolls come in various thicknesses, colors, and sizes. Some are suitable for heavy items, while others are better for lighter products. For instance, a thicker plastic roll can provide more durability and protection. However, it might be more expensive and less flexible. On the other hand, thinner rolls offer cost savings but may lack strength.

Additionally, consider the environmental impact of your choice. With rising concerns about plastic waste, many seek eco-friendly options. Reflecting on your choices may lead to better decisions. It's important to balance cost, performance, and sustainability. Ultimately, the right plastic roll can enhance your packaging strategy.

Choosing the right plastic roll for packaging can be challenging. Various types of plastic rolls serve different purposes. Understanding these types is crucial for effective packaging.

Polyethylene rolls are common. They are versatile and affordable. They come in various thicknesses and sizes. Stretch films are another option. These films cling tightly to products. They protect items during transport while reducing waste. Bubble wrap rolls provide cushioning for fragile items. Their air-filled pockets absorb impacts well.

Sometimes, you might overlook specific needs. For instance, not all plastics are recyclable. It is important to consider sustainability. You might choose a less eco-friendly option inadvertently. Rethinking material choices can improve your environmental impact. Balancing durability and sustainability is essential. Ultimately, your decision should reflect your packaging goals and the product being packaged.

When selecting the right plastic roll for packaging, evaluating thickness and durability is essential. Thickness often dictates how well a material can withstand transportation. Industry reports indicate that plastic films with a thickness of 200 microns or more offer better puncture resistance. This is crucial for fragile items. Choosing the right thickness can prevent costly damages and returns.

Durability determines how well the packaging protects its contents. For instance, a standard LDPE film may provide flexibility but lacks strength under extreme conditions. In contrast, high-density polyethylene (HDPE) films often feature enhanced durability. Research shows that 70% of consumers prefer packaging that minimizes product damage. This highlights the importance of sourcing the right material.

The challenge lies in balancing thickness and cost since thicker films can increase expenses. Some packaging experts recommend trial runs with various thicknesses to identify the optimal solution. Each product is unique, and what works for one may not suit another. Hence, careful evaluation is critical for achieving effective packaging solutions.

| Plastic Type | Thickness (Microns) | Durability Rating | Best Use Cases |

|---|---|---|---|

| LDPE (Low-Density Polyethylene) | 50-100 | Moderate | Grocery bags, packaging films |

| HDPE (High-Density Polyethylene) | 100-300 | High | Containers, bottles, pipes |

| PP (Polypropylene) | 80-200 | High | Food containers, reusable bags |

| PET (Polyethylene Terephthalate) | 200-400 | Very High | Drink bottles, packaging |

| PVC (Polyvinyl Chloride) | 100-300 | Moderate | Pipes, windows, packaging |

When selecting a plastic roll for packaging, cost is a vital consideration. Industry reports indicate that packaging costs can account for 10-30% of total product expenses. Therefore, spending wisely on plastic rolls becomes crucial. Many companies find themselves under pressure to minimize costs, but this often leads to subpar material choices. Such decisions might impact the product's integrity and ultimately the brand's reputation.

Pricing variations exist among different plastic materials. For instance, a study from the Flexible Packaging Association shows that polyethylene is often cheaper than polycarbonate. However, these savings might cost more in the long run. Low-quality materials can lead to product damage or spoilage. Not all cheap options deliver the desired protection for your products, making it essential to weigh quality against price carefully.

Budgeting for packaging also involves more than just the roll price. Hidden costs, like waste and handling, can add up. Reports suggest that businesses may lose an average of 5% of their packaging return because of poor choices. These factors highlight the need for a holistic approach. Organizations should conduct thorough cost-benefit analyses, incorporating both direct and indirect expenses associated with their packaging decisions.

This chart displays the estimated costs for various types of plastic rolls used in packaging, helping businesses assess their budget considerations when selecting materials.

When choosing the right plastic roll for packaging, it's essential to consider environmental factors. Material impacts on the planet cannot be ignored. According to a recent report by the European Commission, plastic waste accounts for 22% of the total waste produced in Europe. This staggering statistic points to an urgent need for sustainable choices in packaging.

Different types of plastic rolls have distinct environmental footprints. For example, polyethylene (PE) is widely used due to its versatility but may take hundreds of years to decompose. In contrast, biodegradable options, while gaining popularity, still pose challenges. A circular economy report highlights that biodegradables only account for about 6% of the market share. This raises questions about their actual effectiveness and long-term sustainability.

Another critical factor is energy consumption during production. Plastic production contributes significantly to carbon emissions. A study published by the International Energy Agency indicated that plastic production could emit up to 1.8 gigatons of CO2 annually by 2030. These figures compel us to reflect on our choices in material selection. What are we really prioritizing – convenience, cost, or the environment? The implications are significant, and each choice matters dearly.

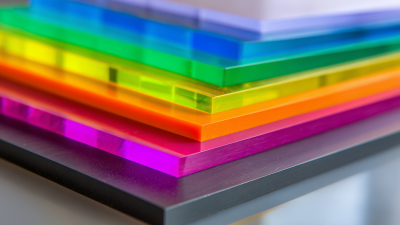

When selecting the right plastic roll for packaging, customization plays a vital role. Many industries now recognize that tailor-made solutions enhance product protection. A recent study found that 79% of businesses believe personalized packaging improves brand perception. Customization options can vary widely, from thickness and size to color and print. Companies need to consider their unique needs before making a decision.

Color choices can significantly impact a product's shelf appeal. A survey indicates that customers are 93% more likely to engage with visually appealing packaging. Clear plastic rolls are great for showcasing products, while opaque rolls can provide security. Brands that opt for printed designs gain a competitive edge. However, finding the right balance is crucial; oversaturated colors can overwhelm potential buyers.

Another factor to ponder is sustainability. The demand for eco-friendly materials is rising. Research shows that 72% of consumers prefer products with sustainable packaging. Companies that adapt to these preferences may see higher customer loyalty. However, not all biodegradable options work well for every product. This area requires careful consideration to avoid negative feedback. Balancing innovation and practicality remains a challenge for many businesses venturing into customized packaging solutions.