Choosing the right thick plastic roll can significantly impact efficiency in various industries. According to industry reports, the demand for high-quality plastic rolls has increased by 25% in the last two years. This surge reflects the need for durable and versatile materials. Thick plastic rolls are widely used in packaging, construction, and manufacturing.

When selecting a thick plastic roll, consider the specific requirements of your application. For instance, the thickness and width can affect durability and performance. A wrong choice can lead to wastage or inadequate protection. It’s essential to assess both quality and cost-effectiveness. Reports show that businesses often overlook thickness specifications, which can lead to subpar outcomes and increased overhead costs.

Understanding the nuances of thick plastic rolls is crucial for making informed decisions. Besides, it's important to reflect on past choices that may not have met expectations. By carefully evaluating options and aligning them with your needs, you can find the perfect thick plastic roll that supports your operational goals.

When exploring thick plastic rolls, it's essential to understand the types available in the market. Common options include polyethylene, polypropylene, and vinyl materials. Each type has unique durability and flexibility traits suited for specific applications. Polyethylene is often chosen for its moisture-resistant qualities, making it perfect for outdoor use. In contrast, polypropylene offers better chemical resistance, making it ideal for industrial settings.

Tips: Determine your project's requirements before choosing a material. Consider factors such as UV exposure, weight, and thickness. Investing in a higher quality roll may save costs in the long run.

Examining industry reports reveals that the demand for thick plastic rolls has surged in logistics and packaging sectors. This growth is attributed to the rise in e-commerce and the need for reliable protective materials. However, buyers often overlook potential disposal issues linked to plastic. Reflecting on sustainability can guide smarter choices for your projects. Choosing recycled materials or biodegradable options can have a positive environmental impact.

| Type of Thick Plastic Roll | Thickness (mil) | Applications | UV Resistance | Price Range ($ per roll) |

|---|---|---|---|---|

| Polyethylene (PE) | 6 - 12 | Tarps, Ground Covers | Low - Moderate | 20 - 50 |

| Polyvinyl Chloride (PVC) | 10 - 30 | Protective Covers, Curtains | High | 30 - 80 |

| Polypropylene (PP) | 5 - 25 | Packaging, Bags | Moderate | 15 - 40 |

| Low-Density Polyethylene (LDPE) | 8 - 20 | Wraps, Liners | Low | 10 - 30 |

| High-Density Polyethylene (HDPE) | 10 - 50 | Construction, Agriculture | High | 25 - 60 |

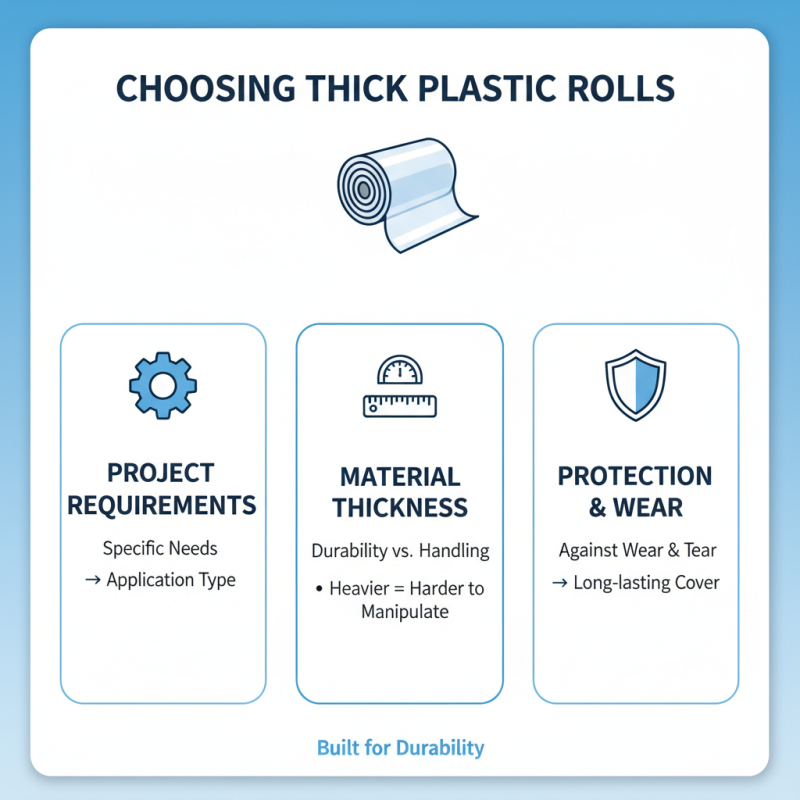

When choosing thick plastic rolls, several key factors come into play. It’s crucial to consider your project’s specific requirements. Think about the thickness you need. Thicker rolls provide better durability but can be harder to manipulate. For instance, if you’re covering a large area, heavier materials might be challenging to handle. Yet, they offer protection against wear and tear.

The type of plastic also matters. Different plastics have varying resistance to moisture, UV rays, and chemicals. For outdoor projects, UV resistance is vital. However, for indoor uses, moisture resistance could be more significant. Make sure to assess your environment.

Tips: Check the product specifications. Look for detailed descriptions. Ask questions if needed. If you find yourself unsure, consider ordering samples. This can help you feel the material before committing. Remember, every project is unique. Reflect on what works best for you. Sometimes, a less popular option may serve your needs better than mainstream choices.

When it comes to choosing a thick plastic roll, evaluating thickness and durability is essential. Different projects require varying levels of protection. A garden tarp, for instance, may need a thicker option to withstand harsh weather. However, using overly thick plastic can lead to unnecessary waste. Finding that balance matters.

Consider the specific use of the plastic roll. For heavy-duty applications, a thicker product is often necessary. But for light-duty tasks, such as covering furniture during a move, a thinner roll might suffice. The thickness often correlates with durability. Thicker materials can resist tears and punctures better. Yet, not all thick plastics are created equal; some may not hold up under UV exposure.

Reflecting on your needs is vital. Ask yourself about the environment where the roll will be used. Will it be exposed to moisture or extreme temperatures? Each factor influences your choice. Sometimes, people overlook the quality of the material, focusing solely on thickness. This can lead to frustration later. Always take time to evaluate all aspects before making a decision.

Thick plastic rolls are essential in various industries. They offer durability and versatility. Often used in construction, agriculture, and packaging, these rolls provide protection against moisture and environmental factors. The global plastic film and sheet market is expected to reach over $100 billion by 2025, illustrating the growing reliance on these materials.

In construction, thick plastic rolls serve as vapor barriers. They shield building materials from moisture. A study reports that improper moisture control can lead to structural damage, resulting in thousands of dollars in repairs. Choosing the right thickness can significantly impact effectiveness. Many experts suggest using at least 10-mil thickness for optimal performance.

In agriculture, thick plastic rolls are used for greenhouse covers and mulching. They help control soil temperature and moisture levels. This contributes to higher crop yields. However, choosing the incorrect roll can hinder growth. Users should ensure compatibility with their specific crops.

Tips: Always consider the environment where the plastic will be used. Not all thicknesses work in every situation. For example, thinner rolls may tear easily under heavy winds in agricultural settings. Experimenting with different options can lead to better results. A little research goes a long way.

When choosing a thick plastic roll, cost and quality are pivotal. Not all rolls are created equal. Some options may seem cheaper, but they can end up costing more over time. When a roll wears out quickly, you’ll spend again. This can be frustrating.

Consider the thickness of the plastic. A denser material often provides better durability. It resists tearing and puncturing. However, thicker plastic rolls usually come with higher price tags. Think about the project you have. Will a lightweight option suffice, or do you need something robust? Finding that balance is crucial.

Delivery time also matters. Some suppliers offer quick shipping but increase prices. Compare this with options that provide slower but more economical delivery. Quality materials may take longer to arrive. Ask yourself: Are the savings worth the wait, or do you need the product immediately? Reflecting on these details can help narrow your choices and improve satisfaction.