When selecting the right HDPE board for your project, considerations are crucial. Industry expert John Smith, a leader in polymer technology, emphasizes, "Choosing the right HDPE board can make or break your project." His insight highlights the importance of understanding your specific needs.

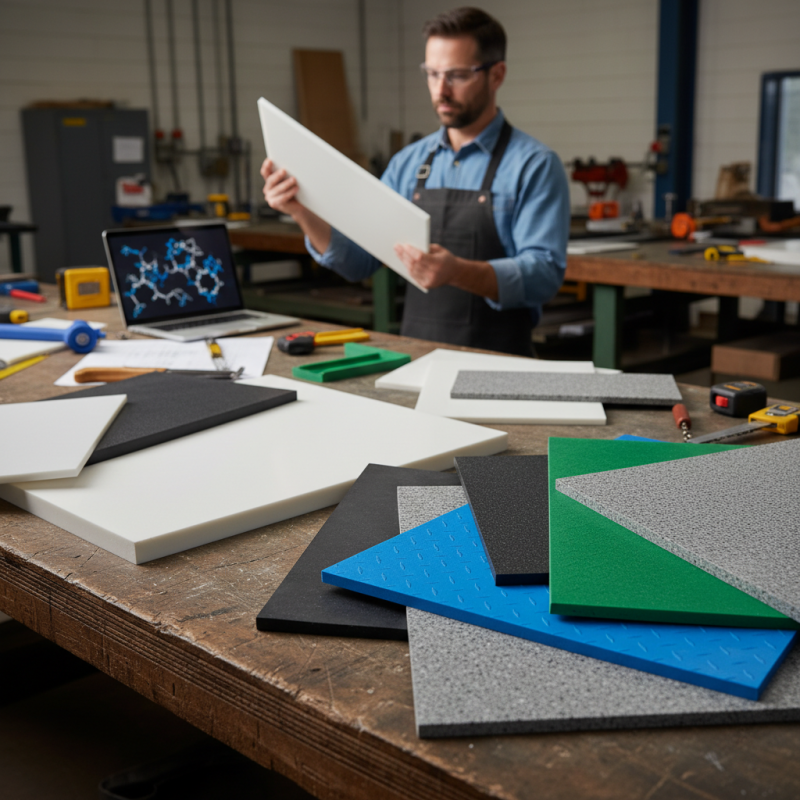

HDPE boards offer versatility for various applications. They are durable, weather-resistant, and cost-effective. However, not all HDPE boards are created equal. Factors such as thickness, color, and surface texture can greatly impact performance. For instance, a thicker board may provide better support but could be heavier and harder to work with. Some projects might require a more textured surface for better grip.

Recognizing the nuances of HDPE boards is essential, yet many overlook the details. Selecting the wrong type can lead to issues down the line. Consider your project's unique demands carefully. Reflect on what you truly need rather than what is readily available. Making the right choice requires both knowledge and sometimes, trial and error.

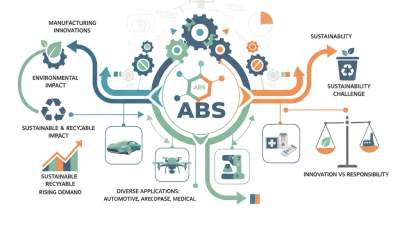

When selecting HDPE boards for any project, understanding their properties is vital. High-Density Polyethylene (HDPE) is known for its durability and resistance to impact and moisture. According to a report by the Plastics Industry Association, HDPE is one of the most recycled plastics, contributing to sustainability efforts. Its chemical resistance makes it ideal for various applications, from outdoor furniture to industrial uses.

Tip: Always consider the thickness and size of the HDPE board. They come in various dimensions, which can impact your project's overall effectiveness. A thicker board may provide better durability but could also be more challenging to work with. Take the time to balance strength and manageability.

The benefits of HDPE boards extend beyond toughness. Their low maintenance requirements save time and resources. Projects using HDPE boards often see a longer lifespan, minimizing replacements. However, the initial cost can be a downside. Evaluate your budget against the long-term savings to ensure you make a sound investment.

Tip: Conduct tests on samples before committing to large orders. This practice can help identify any potential issues early, such as flexibility or color fading. It's an important step that can prevent costly mistakes.

When selecting an HDPE board, understanding the different grades is essential. HDPE boards are categorized into grades based on density and performance. For instance, the most common grades include standard, structural, and industrial. Each grade serves specific applications. While standard HDPE is suitable for general use, structural grades offer higher impact resistance.

Industry reports indicate that structural HDPE can withstand temperatures up to 200°F, making it ideal for outdoor projects. In contrast, standard HDPE often warps under extreme heat. This points to a critical consideration: the environment in which the board will be used. Applications in high-traffic or extreme conditions may necessitate a higher-grade option.

However, using higher-grade materials comes with increased costs. Some projects may not justify the price difference. An evaluation of your project's requirements, including load-bearing needs and exposure to elements, is crucial. Overestimating these needs can lead to overspending and wasted resources. Making informed decisions can lead to cost-effective choices while meeting performance goals. Ultimately, it’s about balancing cost and quality.

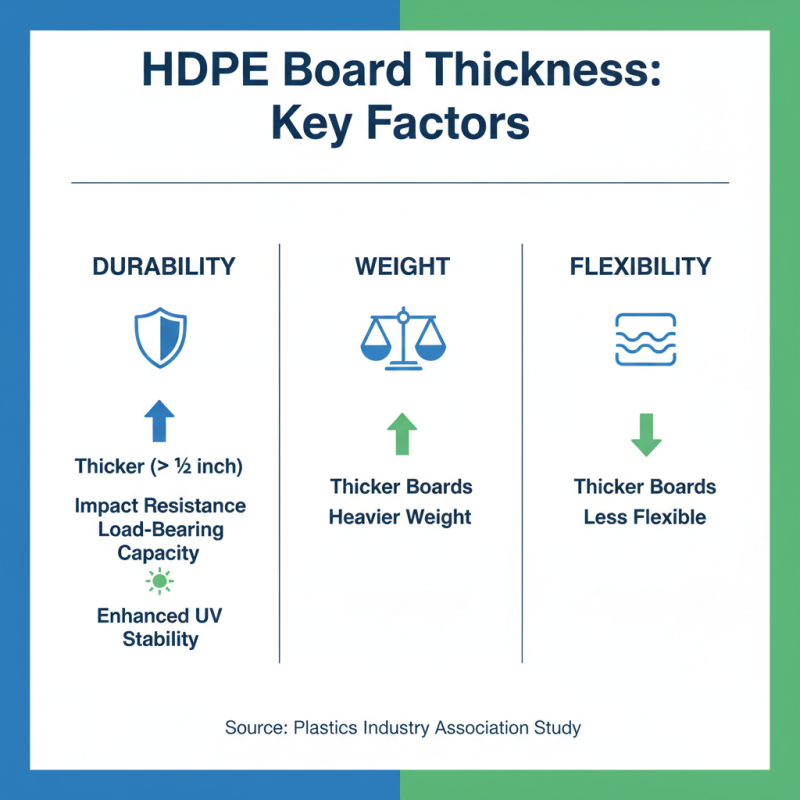

Choosing the right HDPE board for your project is crucial for ensuring durability and functionality. The thickness of the board plays a significant role. Thicker boards typically offer better strength and resistance to impact. According to the American Plastics Council, HDPE boards with a thickness of 0.5 inches or more are ideal for heavy-duty applications.

Weather resistance is another key factor. HDPE boards are known for their resistance to moisture, sunlight, and chemicals. This makes them suitable for outdoor uses, like playgrounds and marine applications. The durability rating of HDPE can vary widely; boards rated for industrial use can last 10-20 years under severe conditions.

Tips: Always check the UV stabilization of the board. This will ensure longevity against sun exposure. Look for boards with a warranty or guarantee for added peace of mind. Keep in mind that while HDPE is durable, it can scratch easily. This is something to consider based on your project's needs. Not all HDPE boards are created equal, so thorough research is essential.

When choosing an HDPE board, thickness plays a crucial role. Thickness impacts durability, weight, and flexibility. Industry reports indicate that boards thicker than ½ inch offer better resistance to impact and higher load-bearing capabilities. According to a study by the Plastics Industry Association, thicker boards tend to last longer in outdoor applications due to their enhanced UV stability.

In contrast, thinner sheets may be suitable for lightweight applications. These boards can be easier to handle and cut. However, using them in high-stress environments may lead to premature failure. A recent analysis highlighted that 30% of users experienced structural issues with boards under ¼ inch in critical situations.

It's essential to weigh the specific demands of your project. For instance, if you need a board for water exposure, thicker options with better seals are preferable. But achieving the right balance between thickness and flexibility is not always straightforward. Many beginners overlook this aspect and face unexpected challenges in their projects. Careful selection can mitigate these risks.

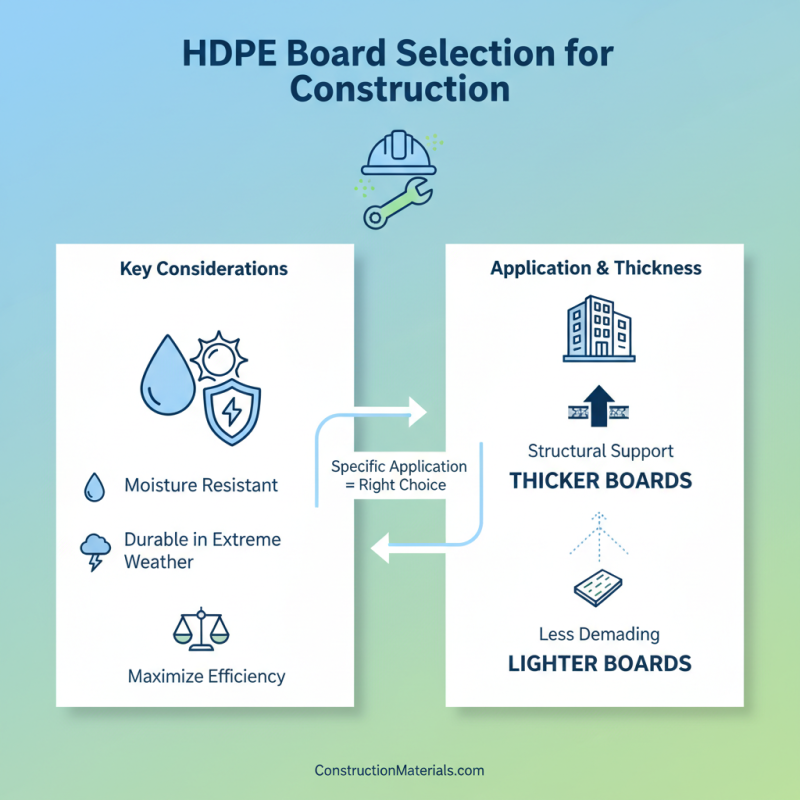

When selecting the right HDPE board, consider the specific application to maximize efficiency. In construction, HDPE boards serve as excellent barrier materials. They resist moisture and are durable against extreme weather. Choose thicker boards for structural support. However, lighter boards may suffice for less demanding applications.

In the food industry, HDPE is commonly used for cutting boards and surfaces. It is non-porous and easy to clean. However, not all grades are equal. Some may not meet food safety standards. Testing and certification can prevent hygiene issues. Additionally, consider the color and texture, as these factors can impact usability and maintenance.

In landscaping, HDPE boards provide great versatility. They can be used for planter boxes, borders, and more. Their resistance to chemicals and rot is beneficial. However, ensure that the chosen HDPE is UV-stabilized to avoid degradation. Selecting the wrong type can lead to short lifespan or higher replacement costs. Always reflect on the long-term impact of your choice.