In the realm of modern manufacturing, the use of vacuum forming plastic sheets has emerged as a vital process, offering unparalleled versatility and efficiency. This innovative technique allows for the rapid production of complex shapes and custom designs, making it a preferred choice for industries ranging from automotive to consumer products. As manufacturers seek to optimize their operations and enhance product offerings, understanding the intricacies of vacuum forming plastic sheets becomes essential. This guide aims to demystify the vacuum forming process, providing a comprehensive overview of its principles, applications, and best practices. Whether you are a seasoned professional or new to the field, this essential resource will equip you with the necessary knowledge to leverage vacuum forming techniques effectively, ensuring your manufacturing processes stand out in an increasingly competitive landscape.

Vacuum forming is a versatile and efficient technique widely used in modern manufacturing to create detailed and complex shapes from plastic sheets. This process involves heating a thermoplastic sheet until it becomes pliable, then using a vacuum to mold it against a specific form or mold. According to a recent industry report by Mordor Intelligence, the global vacuum forming market is expected to grow at a CAGR of 4.6% from 2021 to 2026, highlighting its increasing relevance in sectors like automotive, packaging, and consumer products.

The principles behind vacuum forming are relatively straightforward but crucial for effective production. The process begins with the selection of appropriate thermoplastic materials, such as ABS or polycarbonate, each offering unique properties suitable for different applications. Temperature control is vital, as precise heating ensures the material reaches its optimal forming point without degradation. Furthermore, the vacuum force must be carefully calibrated to ensure an even distribution across the mold, achieving a perfect fit. Recent advancements in technology have introduced automated vacuum forming systems that significantly enhance production speed and accuracy, leading to reduced waste and increased efficiency.

When it comes to vacuum forming, choosing the right plastic sheets is critical to the success of your manufacturing process. According to a report by MarketsandMarkets, the global vacuum forming market is projected to reach $3.74 billion by 2024, underscoring the importance of selecting the appropriate materials. Common materials for vacuum forming include ABS (Acrylonitrile Butadiene Styrene), HIPS (High Impact Polystyrene), and PETG (Polyethylene Terephthalate Glycol), each offering different properties that can affect durability, flexibility, and appearance.

When it comes to vacuum forming, choosing the right plastic sheets is critical to the success of your manufacturing process. According to a report by MarketsandMarkets, the global vacuum forming market is projected to reach $3.74 billion by 2024, underscoring the importance of selecting the appropriate materials. Common materials for vacuum forming include ABS (Acrylonitrile Butadiene Styrene), HIPS (High Impact Polystyrene), and PETG (Polyethylene Terephthalate Glycol), each offering different properties that can affect durability, flexibility, and appearance.

Tips: When selecting plastic sheets, consider the specific application and the environmental conditions the final product will encounter. For instance, ABS is favored for its toughness and impact resistance, making it a great choice for durable products, while PETG is known for its clarity and is ideal for applications requiring transparency.

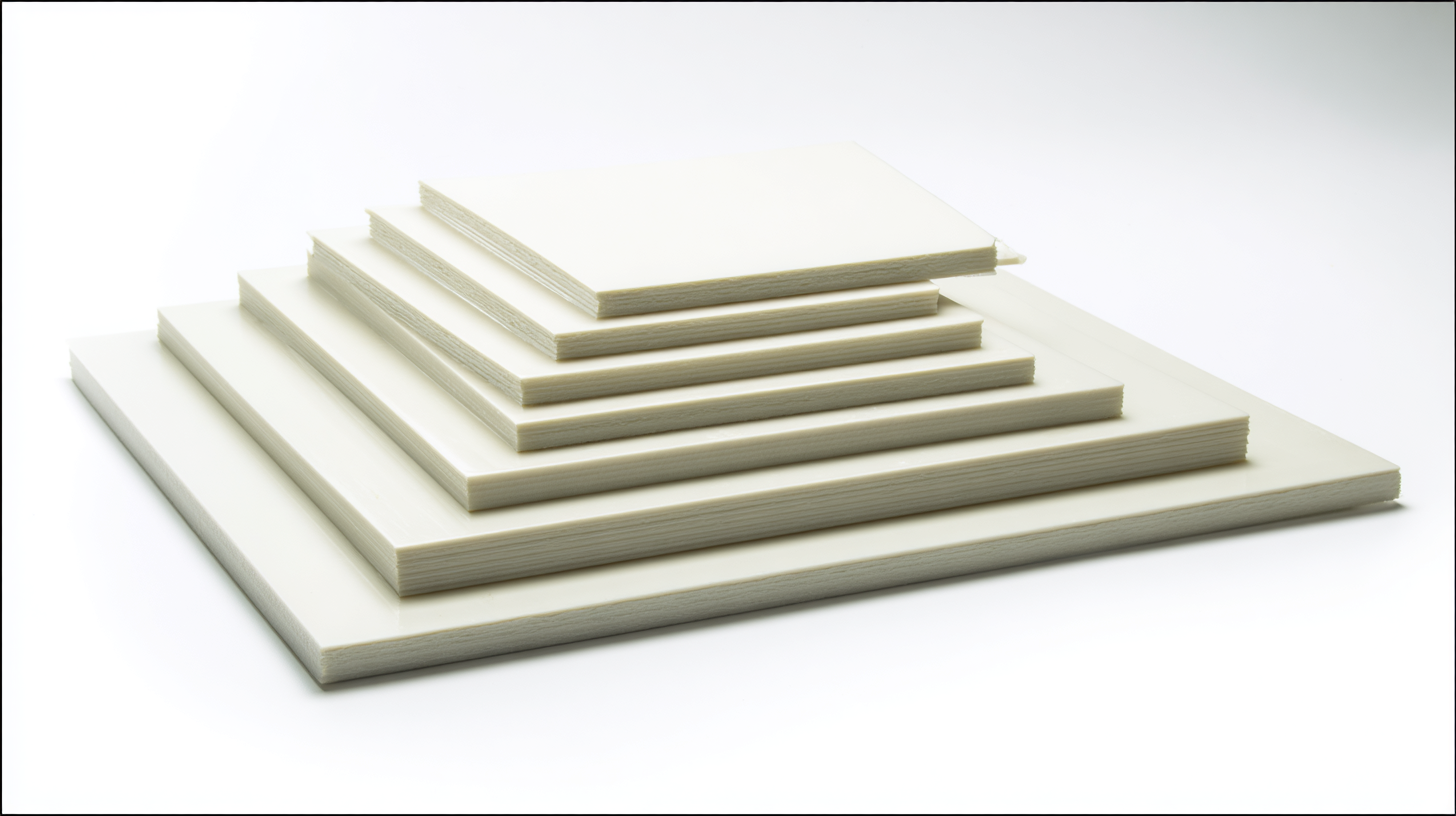

Additionally, it is vital to assess the thickness of the sheets, as this can influence both the ease of forming and the final part strength. A study from the American Society of Plastics Engineers emphasizes that thinner sheets may allow for more intricate designs but can compromise strength, whereas thicker sheets provide improved durability but may limit complexity.

Tips: It's advisable to conduct initial tests with various thicknesses to find the ideal balance between design flexibility and product integrity. Understanding these materials and their properties will enable manufacturers to optimize their production processes and produce high-quality vacuum-formed components.

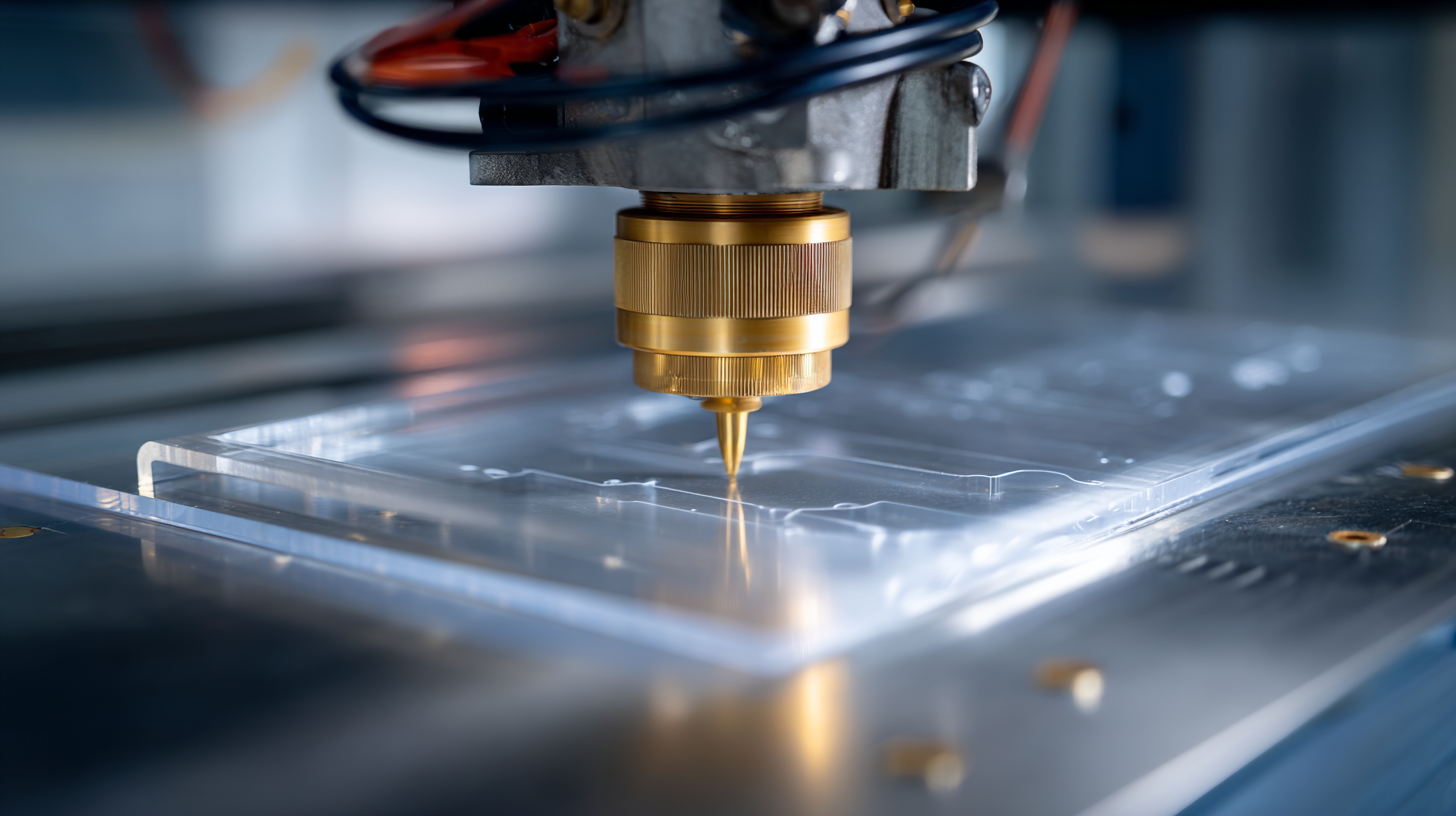

When it comes to vacuum forming plastic sheets, understanding design considerations is crucial for achieving efficient and effective results. The shape of the item being formed plays a significant role in determining the overall success of the process. Designers should prioritize geometries that allow for easy material flow and minimize undercuts, as complex shapes can lead to difficulties during forming and removal. Utilizing gentle curves rather than sharp angles can enhance the flow of the heated plastic, ensuring even thickness and reducing the risk of material weak points.

Additionally, the structure of the mold should be carefully planned to facilitate the vacuum forming process. This includes selecting appropriate materials for the mold that can withstand the required temperatures and pressures. Incorporating features such as draft angles can aid in demolding, while strategically placed vents help prevent air traps that could compromise the integrity of the formed part. By paying attention to these design details, manufacturers can optimize their vacuum forming processes, resulting in high-quality products that meet modern manufacturing demands.

Quality control in vacuum forming is paramount for achieving precision and durability in the final products. According to a recent report from Smithers Pira, the global market for vacuum-formed plastics is projected to reach $3.5 billion by 2025, underscoring the growing demand for high-quality manufacturing processes in various industries. This increasing demand places significant pressure on manufacturers to implement rigorous quality control measures to ensure that the vacuum-formed components meet the exact specifications and performance criteria required in modern applications.

One effective approach to enhance quality control is through real-time monitoring during the vacuum forming process. Advanced technologies, such as automated inspection systems and machine learning algorithms, can detect anomalies in product dimensions and thickness. A study by the Society of Plastics Engineers indicated that incorporating automated inspection can reduce defect rates by up to 30%. Additionally, thorough material testing and adherence to industry standards, such as ISO 9001, can further bolster the durability of vacuum-formed products, ensuring they perform optimally under various conditions while maintaining customer satisfaction.

| Parameter | Value | Measurement Unit |

|---|---|---|

| Sheet Thickness | 2.5 | mm |

| Cycle Time | 60 | seconds |

| Temperature | 180 | °C |

| Material Type | Acrylic | - |

| Shrinkage Rate | 1.5 | % |

| Tensile Strength | 50 | MPa |

| Impact Resistance | Notched | - |

| Color Options | Transparent, Opaque | - |

Vacuum forming technology has revolutionized modern manufacturing by allowing for the efficient production of complex plastic shapes and components. One of the most innovative applications of vacuum forming is in the automotive industry, where it is used to create lightweight yet durable interior parts. These components not only enhance the vehicle's aesthetic appeal but also contribute to fuel efficiency by reducing overall weight. The ability to produce custom shapes quickly makes vacuum forming an ideal choice for manufacturing prototypes and low-volume runs, which are increasingly common in the automotive sector.

Another significant application lies in the packaging industry. Vacuum-formed trays and clamshells are widely used for their lightweight and protective characteristics, providing an effective solution for packaging delicate items, such as electronics and food products. The customization possibilities offered by vacuum forming allow manufacturers to design packaging that not only secures products but also enhances brand visibility and consumer appeal. This versatility in applications showcases how vacuum forming technology is redefining manufacturing processes across various sectors, driving innovation and sustainability.