In the world of manufacturing, mastering plastic extrusion is crucial. This technique shapes plastic into various profiles and components. Experts emphasize its importance for efficiency and production quality. Tim Green, a noted plastic extrusion specialist, once stated, "Understanding the nuances of plastic extrusion can significantly enhance production outcomes."

Plastic extrusion offers unique advantages. It allows for creating complex shapes and maintaining consistency in production. However, many struggle with controlling temperature and pressure during the process. These factors can lead to defects and waste, affecting overall efficiency. Proper training is essential to navigate these challenges.

Continuous learning and adaptation are vital in the plastic extrusion industry. As market demands change, techniques must evolve too. Reflecting on one's processes can reveal areas needing improvement. Small adjustments can lead to substantial benefits in productivity and quality. Embracing these insights can be the key to mastering plastic extrusion.

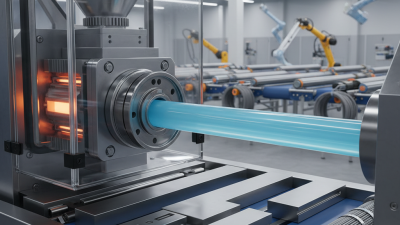

Plastic extrusion is a vital process in manufacturing. Understanding its basics can enhance production efficiency. The process involves feeding plastic materials into a heated barrel. This material melts and is pushed through a die to form various shapes.

Tips: Monitor temperature closely. A slight variation can affect the final product. Ensure consistent material feeding to avoid blockages in the extruder. Regularly check for wear and tear in machinery.

Different types of plastics require different extrusion temperatures and techniques. For example, thermoplastics can be reprocessed. This feature makes them versatile in production. However, adjusting to each type can be challenging.

Tips: When experimenting, document each setting change. This helps identify trends in production quality. Testing small batches before larger runs can save time and resources. Mistakes should be viewed as learning opportunities to refine practices.

Efficient plastic extrusion relies heavily on the right equipment. Key machinery includes the extruder, which melts plastic pellets and forces them through a die. Selecting an extruder with suitable screw design can optimize melting and mixing. This will enhance the quality of the final product, ensuring consistency.

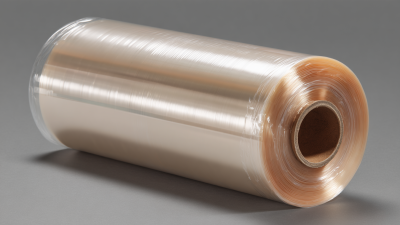

Another crucial component is the die itself. The design of the die affects the shape and thickness of the extruded product. A poorly designed die can lead to uneven products, requiring adjustments and wasted material. Cooling systems are equally important; they solidify the extrudate quickly to maintain shape. Experimenting with different cooling methods can yield better results.

Don’t overlook the importance of auxiliary equipment. Things like material loaders and granulators are often overlooked. Yet, they play a significant role in the overall efficiency of production. If these systems malfunction, the entire process may slow down. The balance between all equipment types is necessary for seamless operation.

| Equipment Category | Equipment Type | Purpose | Key Features |

|---|---|---|---|

| Extruders | Single-Screw Extruder | Melts and shapes plastic | High melting efficiency |

| Extruders | Twin-Screw Extruder | Compounds and blends materials | Excellent mixing capability |

| Cooling Equipment | Water Cooling System | Cools down extruded materials | Efficient cooling |

| Sizing Equipment | Calibration Table | Shapes the final product | precise dimensions |

| Cutting Equipment | Cutter | Cuts material to desired length | Adjustable cutting speed |

| Control Systems | PLC Control System | Monitors and regulates the process | User-friendly interface |

Plastic extrusion is a complex process influenced by several key factors. Temperature control is crucial. If the temperature is too high, the material degrades. If it's too low, the flow may be insufficient, leading to defects. Every change in temperature can affect the final product's quality. Monitoring this variable is essential for consistent results.

Another important element is the material choice. Different plastics behave uniquely under heat and pressure. A poor selection can result in weak or brittle products. Understanding the material properties is vital. You might also need to consider additives, which can enhance performance but may complicate the extrusion process.

Moreover, die design plays a significant role. An improperly designed die can create uneven flow. This can lead to variations in thickness or surface imperfections. Testing and refining die shapes can be necessary to achieve optimal results. Each adjustment should be evaluated carefully to ensure improved performance.

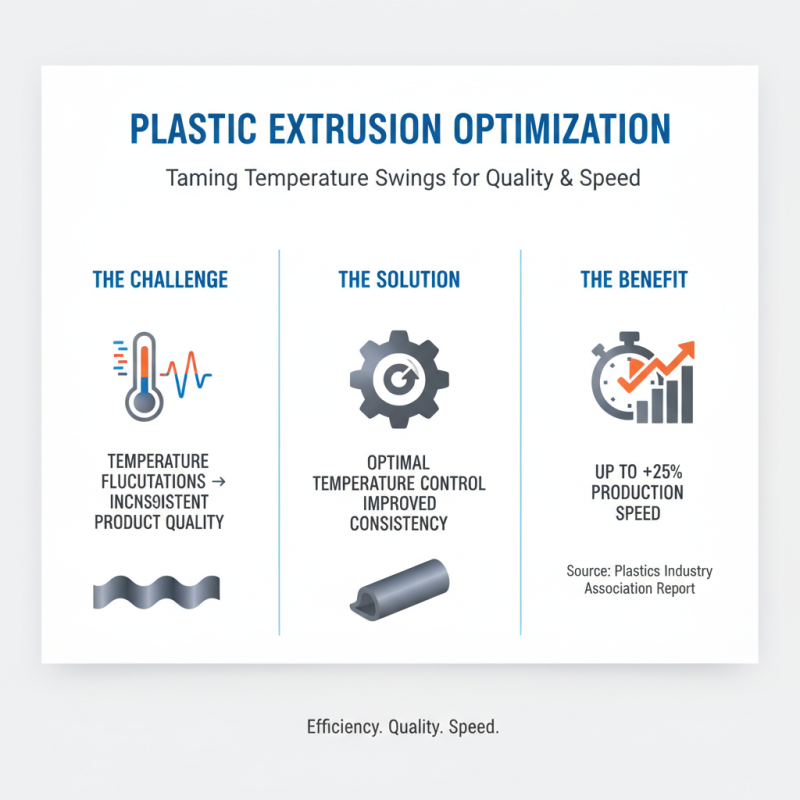

Plastic extrusion is a widely used technique that comes with its own set of challenges. Common issues like temperature fluctuations can lead to inconsistent product quality. In fact, a report from the Plastics Industry Association has shown that maintaining optimal temperatures can improve production speed by up to 25%.

Another challenge is material waste. Many manufacturers struggle with scrap rates, which can exceed 15% in some cases. Implementing better material handling methods and ensuring precise measurements can mitigate this. Using correct formulas for material blends plays a crucial role in minimizing waste during production.

**Tip:** Regularly check and calibrate your extrusion machines. Small calibration errors can compound over time, leading to significant issues.

Operator training is essential. Often, inexperienced staff contribute to production setbacks. Comprehensive training programs enhance skill levels and reduce errors. A recent study indicated that companies with trained operators had a 30% lower defect rate.

**Tip:** Create a simple visual guide for operators. It can reinforce best practices and serve as a quick reference.

Acknowledging and reflecting on these challenges is the first step toward mastering plastic extrusion. Each problem is an opportunity for improvement, pushing the industry forward.

Mastering plastic extrusion techniques is crucial for efficient production in today’s competitive landscape. Advanced technologies are transforming processes. According to a recent report, optimizing extrusion speeds can improve production efficiency by up to 30%. This highlights the importance of incorporating innovative equipment designs and modern control systems.

Investing in real-time monitoring tools is essential. These tools can identify bottlenecks in production almost immediately. A study found that nearly 25% of production downtime stems from inefficiencies that could be avoided with better oversight. It’s vital to train your team to utilize these systems effectively. Many operators still rely on outdated practices that slow down operations.

Color mixing and material handling often pose challenges. Miscalculations can lead to waste, impacting overall productivity. The industry sees rejection rates of 5-10% due to poor mixing techniques. Implementing automated systems to address these issues may require upfront investment but will pay off in the long run. Reassessing current methodologies regularly will drive continuous improvements.