The versatility of HDPE board has positioned it as a key material across various modern applications, ranging from construction to packaging and beyond. According to a report by Markets and Markets, the global HDPE market is projected to reach $72.48 billion by 2026, indicating a robust growth driven by its unique properties such as high chemical resistance, lightweight nature, and durability. This material is increasingly being utilized in areas like signage, outdoor furniture, and various industrial applications, highlighting its adaptability and effectiveness. Furthermore, the ability of HDPE board to be recycled enhances its appeal in a world that increasingly prioritizes sustainability.

This article will explore the myriad ways in which HDPE board is transforming industries and providing innovative solutions, illustrating why it is becoming an essential component in both commercial and consumer markets.

HDPE (High-Density Polyethylene) board has gained popularity across various industries due to its unique properties that enhance both functionality and efficiency. Its exceptional resistance to chemicals and moisture makes it ideal for use in environments where harsh substances are present, such as in chemical manufacturing and wastewater treatment facilities. The durability of HDPE allows for long-term use without significant wear and tear, making it a preferred material for outdoor applications like playgrounds and park benches.

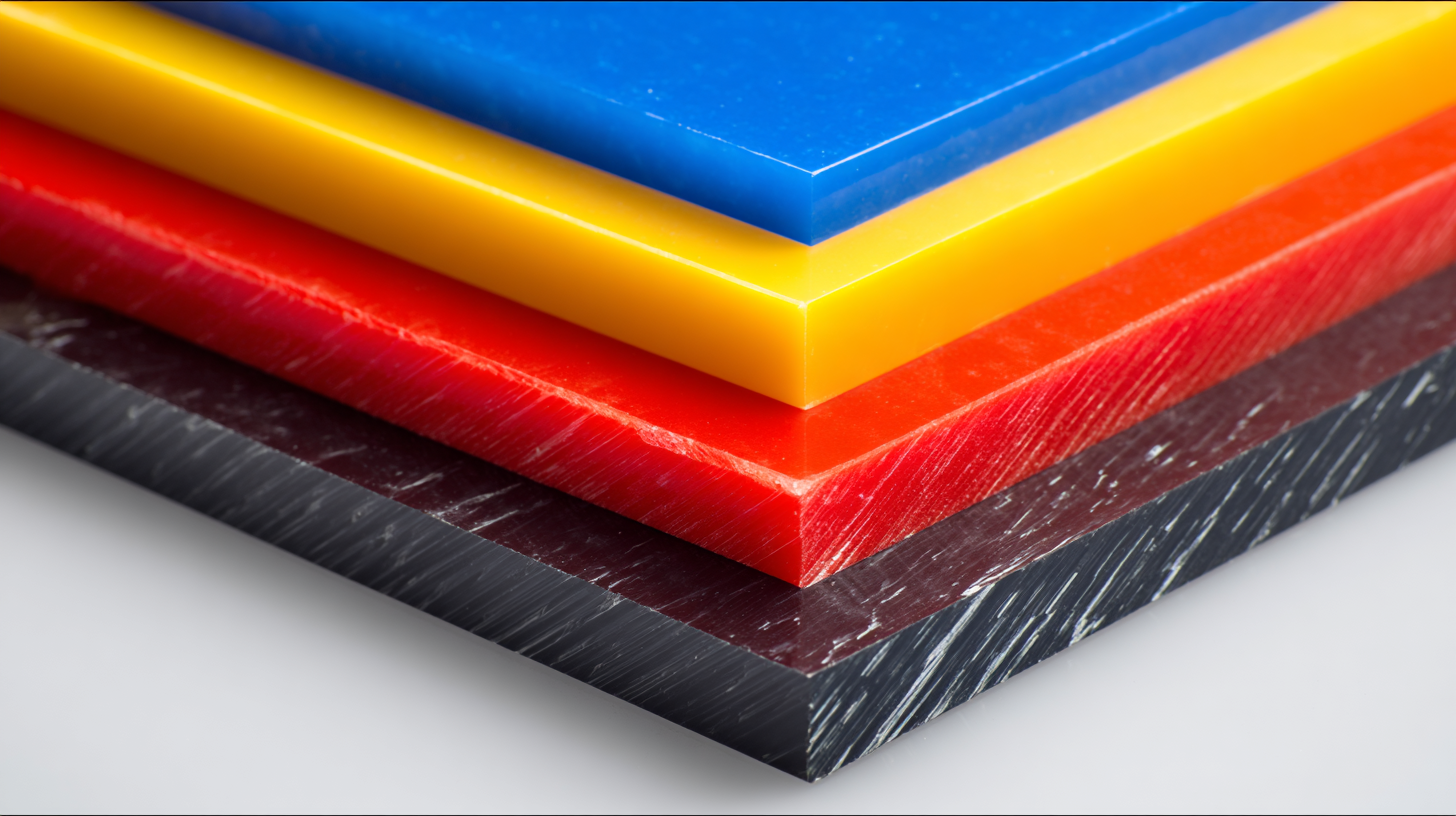

Moreover, HDPE boards are lightweight yet incredibly strong, offering a practical solution for construction and transportation industries. Their flexibility in design enables manufacturers to produce custom-sized boards tailored to specific project requirements. Additionally, the sustainability aspect of HDPE cannot be overlooked; being recyclable, it contributes to eco-friendly practices, further enhancing its appeal in sectors focused on environmental responsibility. From signage and packaging to marine applications, the versatility of HDPE board positions it as a critical material across modern applications.

Moreover, HDPE boards are lightweight yet incredibly strong, offering a practical solution for construction and transportation industries. Their flexibility in design enables manufacturers to produce custom-sized boards tailored to specific project requirements. Additionally, the sustainability aspect of HDPE cannot be overlooked; being recyclable, it contributes to eco-friendly practices, further enhancing its appeal in sectors focused on environmental responsibility. From signage and packaging to marine applications, the versatility of HDPE board positions it as a critical material across modern applications.

When selecting the right HDPE board for your project, it’s crucial to consider factors such as thickness, density, and intended use. According to a report by the American Plastics Council, HDPE (High-Density Polyethylene) boards exhibit an impressive density range of 0.94 to 0.97 g/cm³, making them lightweight yet robust. This characteristic allows for a variety of applications, from outdoor furniture to industrial components. For projects demanding weather resistance and durability, selecting a thicker board—typically between 1/2 inch to 1 inch—can significantly enhance performance.

Additionally, understanding the specific properties required for your application is key. For instance, an industry study published in the Journal of Plastic Engineering highlighted that using recycled HDPE boards can lead to a 30% reduction in overall project costs while maintaining structural integrity. When choosing the right board, assess your project's load-bearing requirements and environmental conditions. Matching these needs with the right density and thickness will ensure that your HDPE board performs effectively, providing longevity and value over time.

| Application | Thickness (mm) | Sheet Size (mm) | Color Options | Key Features |

|---|---|---|---|---|

| Outdoor Signage | 3-20 | 1220 x 2440 | Black, White, Green | UV Resistant, Waterproof |

| Food Packaging | 1-10 | 1000 x 2000 | Natural, Blue, Red | FDA Approved, Easy to Clean |

| Construction | 6-25 | 1220 x 2440 | Black, Gray | Impact Resistant, Durable |

| Containers and Crates | 4-12 | 900 x 1200 | Green, Blue, Yellow | Lightweight, Recyclable |

| Marine Applications | 8-20 | 1200 x 2400 | Black, White | Chemical Resistant, High Strength |

High-density polyethylene (HDPE) board has emerged as a game-changer in construction and design, widely recognized for its durability, chemical resistance, and low environmental impact. According to a report by the Plastics Industry Association, the demand for HDPE products in the construction sector is projected to grow by nearly 5.2% annually through 2025. This growth can be attributed to HDPE's ability to withstand harsh weather conditions and its resistance to corrosion, making it ideal for various applications such as structural elements, signage, and even protective barriers.

In architectural design, HDPE boards are being increasingly utilized for innovative features that blend functionality with aesthetic appeal. A study from Markets and Markets highlights the rising trend of using HDPE in furniture design, with the market expected to reach $1.7 billion globally by 2026. Designers favor HDPE boards due to their versatility; the material can be easily cut, shaped, and colored, allowing for creative and sustainable design solutions that meet the demands of modern aesthetics. Furthermore, HDPE's recyclable nature aligns with the growing trend towards sustainability in construction and design, making it a preferred choice for environmentally conscious projects.

HDPE (High-Density Polyethylene) boards have become increasingly popular in various industries due to their durability, versatility, and resistance to environmental factors. To maximize the longevity of HDPE board products, regular maintenance is essential. Here are some practical maintenance tips for ensuring their extended use.

First, ensure that the HDPE boards are kept clean. Regularly wash the surface with mild soap and water to remove dirt, dust, and any stains. Avoid using abrasive cleaners or scrubbers, as these can scratch the surface, leading to faster wear. Additionally, addressing spills and stains promptly will help maintain the board’s appearance and prevent potential damage.

Another vital tip is to prevent exposure to excessive heat and direct sunlight for prolonged periods. While HDPE is designed to withstand various conditions, extreme temperatures can lead to warping or discoloration. Use protective coverings when the boards are not in use, especially in outdoor settings, to shield them from UV rays and temperature fluctuations. By following these simple maintenance practices, users can ensure the longevity and functionality of their HDPE board products for years to come.

In the realm of modern materials, HDPE (High-Density Polyethylene) board stands out for its durability and versatility, particularly when contrasted with other options like plywood or metal. Unlike traditional wood, HDPE board is water-resistant, preventing mold and decay, making it an ideal choice for outdoor applications such as signage, playground equipment, and marine environments. Its light weight combined with a high strength-to-density ratio allows for easier handling and installation compared to heavier materials, which can be cumbersome in many projects.

When compared to metals, HDPE also offers advantages, especially in terms of cost and corrosion resistance. While metals such as aluminum or steel provide strength, they can succumb to rust and weathering, necessitating expensive coatings or maintenance. HDPE’s resilience to chemicals and UV damage enhances its appeal in industrial settings, where exposure to harsh substances is common. Overall, HDPE board presents a compelling alternative in various applications, demonstrating its superiority in many scenarios where traditional materials may falter.